The imaginative, multi skilled, creative and professional approach of ASF stands out when working on bespoke coordinated projects. With attention to detail held as a key ideal and a knowledge of the combined importance of durability alongside finish, texture and form, ASF has the savvy to take an idea from concept to completion.

Projects

From Concept to Completion

- PROJECT:

- Skipton, Coach Street development

- CLIENT:

- O’Callaghan

- INFO:

-

ASF were asked to produce the popular ASF 502 cast iron and timber seat, but at a 3m overall length.

- PRODUCTS

& SOLUTIONS: -

This seat is designed to be 1.8 metres overall length, and whilst we could use longer timbers to extend this, anything much over 2 metres would not be suitable for use, leaving the timbers springy and unsupported which would significantly lower their expected lifespan.

Using an intermediate arm/leg casting allowed us to manufacture a 3 metre long seat made up of 2 conjoined 1.5 metre seat pans. These are not only a practical solution to a problem, but they look great too. The scale of the chunky cast iron seat ends and intermediate casting works well with the increased size of the seats.

The end result was a bank of 14, 3 metre long seats that fit the brief perfectly in this famous Yorkshire Dales Market Town.

These intermediate castings could also be used to create faceted seats by cutting the timber ends to a mitred finish, or producing curved or circular seats by using bent or profiled timbers.

- PROJECT:

- Hawick Flood Alleviation Scheme

- CLIENT:

- Jacobs

- INFO:

-

ASF were asked to develop a bespoke quayside post for the above scheme. Critically, the post had to be the same measurement on the vertical plane so that the top edge did not interfere with the width of the footpath.

There was also a straight post to match, to be sited on the inland side of the footpath

- PRODUCTS

& SOLUTIONS: -

Following discussions with the engineer ASF came up with a design plan.

ASF first drew the specification of the posts as a 3D model so that the client could successfully envisage the end product.

This was then fine tuned to work to a specific height, plan for post centres and rail configuration. A key issue on this was that whilst the posts needed to be useable quayside posts, they should not off too much of a barrier so that debris when flooding would be caught, potentially worsening a situation.

There were also significant discussions on baseplate sizes and fixing options which culminated in a bespoke fixing.

Rails are to be from polished grade 316 stainless steel, and are supplied with neoprene/nylon spacers to avoid cross metallic contamination.

Posts are to be finished spun galvanised offering an expected maintenance free life in excess of 25 years.

- PROJECT:

- ASF Boston Load Bearing Trough Bollard, Liverpool Football Club

- CLIENT:

- I D Verde / Liverpool FC

- INFO:

-

ASF were already supplying the ram raid resistant version of the popular ASF 5002 stainless steel bollard to this site, when we were approached regarding fold down or removable bollards for the players entrance of the stadium. Initial discussion showed that the ASF 652 Trough Bollard would be most suitable. Even though this standard bollard trough has been used for many years without issue, including use in bus stations and delivery yards, the client wanted more reassurances regarding the load bearing capacity of the trough lid when folded down

- PRODUCTS

& SOLUTIONS: -

ASF have previously developed a trough bollard for use in the USA that meets their H20 loading standards. By US standards this is described as being suitable for 'large trucks and semi's'

This product was proposed for use at the Anfield Football Ground site for the entrance where players and officials vehicles enter and leave the ground, as well as players coaches and some other delivery vehicles.

The ASF Boston Trough was approved and was manufactured to house the same bollard as supplied on the rest of the site so that when in an upright position the continuity of style was perfect.

The ASF Boston Trough Bollard is manufactured to take loads of up to 32,000lbs axle weight, and the site engineers deemed this more than suitable for the passing over of players coaches.

On the same site ASF also manufactured an access ramp for a disabled toilet. The ramp was to fix to the front of a portacabin, and have side skirts and handrailing, but be suitable to be moved in future if necessary. ASF manufactured a unit that is at once bespoke and modular so that it can be moved if the facility moves, and has a good amount of flexibility should the requirements change slightly.

- PROJECT:

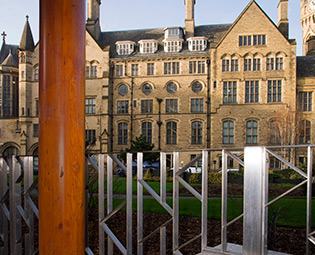

- ASF Bespoke Steel and Stainless Steel Quayside Railings, Birkenhead

- CLIENT:

- Robal Engineering

- INFO:

-

ASF were asked to manufacture a quayside railing to run alongside the Mersey Estuary at Birkenhead. The Railings were to have a quayside curve, horizontal infill bars and be manufactured in mild steel with a stainless steel top rail.

- PRODUCTS

& SOLUTIONS: -

ASF first drew the specification of the railing panels.

Panel uprights were from laser profiled heavy duty steel sheet, that would form the quayside curved profile when upright. The quayside curve is an inward sloping / curving panel that creates an overhang that as such does not make a natural ladder beside the water.

These upright pieces are joined with solid bar horizontal infill bars set at centres that stop people fitting through the gaps whilst avoiding all body trap risks (based on regulatory dimensions).

The panels themselves are finished galvanised and powder coated in a satin finished graphite grey.

The top rail is a mechanically fixed grade 316 stainless steel tube.

Panels were straight and curved in both directions along the run, which meant each panel had to be handmade and each individual horizontal bar and top rail curved to match the quayside itself.

- PROJECT:

- ASF Stowe Post, Roof Terrace and Balcony, Great Portland Street, London

- CLIENT:

- Iconic Build

- INFO:

-

ASF were approached to look at supplying balustrade railings for a roof terrace and fourth floor balcony.

- PRODUCTS

& SOLUTIONS: -

ASF worked through the specification phases to identify a suitable product to use as balustrade railings this project.

The ASF Stowe Post was chosen. It was decided that they be cast in ductile SG iron so that they would comfortably surpass any applicable loading requirements. Site / client engineers approved and signed off this specification and conducted all relevant calculations at their end.

3D specification drawings were produced by ASF in conjunction with the client to correctly specify the product dimensions so they would fit site layout and installation needs

For the roof terraced area the standard root fixed ASF Stowe Post was used, although the root was lengthened by 300mm by the request of the client. On the balcony area a pattern alteration was made so that the posts could be side mounted, being mechanically fixed into exposed structural steelwork on the building.

ASF also supplied lengths of galvanised rail, and a number of bespoke manufactured right-angle returns. Rails were connected using internal rail connectors.

- PROJECT:

- ASF Balmoral Short Panel Post, Salford Quays

- CLIENT:

- Jones Contracts

- INFO:

-

As part of the Salford Quays refurbishment, ASF were supplying a number of stainless steel street furniture elements to the pedestrian and residential areas. The client, knowing we have our own foundry, approached us to look at a cast iron wall top guardrail to run along the top of a section of old industrial walling alongside the Manchester Shipping Canal.

- PRODUCTS

& SOLUTIONS: -

ASF have many options for cast iron posts, and the ASF Balmoral Short Panel Post was chosen as it is decorative and chunky, with a style that ties in nicely with the era when the canal walls were originally built.

These posts were combined with vertical infill panels manufactured from slightly oversize tubing to create a very imposing, but stylish post and panel system

The posts are manufactured in 100% recycled cast iron, with an estimated lifespan in excess of 100 years in normal use and minimal maintenance

- PROJECT:

- ASF 5008 Pedestrian Guardrail, Swansea

- CLIENT:

- Swansea Council

- INFO:

-

ASF were specified to supply a bespoke version of the ASF 5008 Post and Rail system as a Pedestrian Guardrail

- PRODUCTS

& SOLUTIONS: -

Pedestrian Guardrail is often a purely utilitarian product creating a boundary between vehicle and pedestrian areas, but this project asked for a more design led solution to tie in with the stainless steel sculptural elements already on site.

The ASF 5008 bollard is a stylish bollard that has a solid machined top as a design feature. This bollard was chosen to be utilised as the upright for this guardrail system.

The panels themselves were manufactured from stainless steel tube to make the outer frame, with solid stainless steel bars as the uprights.

Panels were rolled to follow the curve of the site which further adds to the striking nature of this job.

Once fixed and welded, and with welds polished back - the system becomes a single sweeping unit with no visible fixings.

The post uprights were finished bead blasted and the tops left with a bright machine finish. The panels were bright polished. The end result is a very low maintenance and visually impressive pedestrian guardrail system.

- PROJECT:

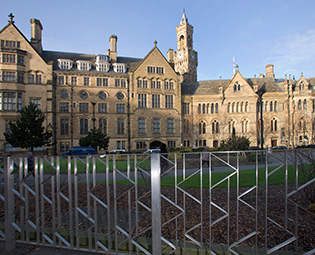

- ASF Glass Balustrade, Bradford Library

- CLIENT:

- Bradford Metropolitan Council

- INFO:

-

ASF were asked to supply glass balustrade to 2 areas on the front promenade of the recently refurbished Bradford Library Buildings

- PRODUCTS

& SOLUTIONS: -

ASF used two types of fixings for the glass balustrade. Channel fixed for an area between slate piers and a side mounting on an area bordering the main stairway to the building

Both systems met full loading specifications

The channel fixings offer an 'invisible' fix with no posts or brackets visible above ground

The side mounted panels have the same effect from the promenade walkway side, and on the stairway side oversized polished stainless steel stud heads were used to make a feature of the fixing points.

Both systems work to compliment the stainless steel street furniture and step units previously supplied by ASF, as well as fitting in with the attractive grey slate piers that form part of the perimeter.

The glass offers a load tested barrier whilst allowing more extensive views across the city to Bradford Town Hall and beyond.

- PROJECT:

- ASF 5006 Step Units, Bradford Library

- CLIENT:

- Bradford Metropolitan Council

- INFO:

-

Over the years ASF have supplied this style of step unit to a number of projects around Bradford and its suburbs. ASF were asked to offer this product to replace some ageing steel handrails that were in already place.

- PRODUCTS

& SOLUTIONS: -

ASF 5006 Handrail is a popular choice for step units as it offers simple and stylish lines whilst the mitred top of the posts gives just enough of a decorative feel to elevate these beyond a simple utilitarian handrail.

Using a 114mm diameter post for the uprights gives the units a sense of permanence that works well with the wide nature of the steps.

Single and double handrails were made to measure for fitting onto 3 areas of stairway. ASF mitred the top of the posts on the risers but supplied flat topped posts on the level areas, just to give that genuinely bespoke feel.

The main stairway has a centrally mounted double handrail full wrapped at top and bottom with 50mm tube. All joins and fixings are welded and polished back on site to provide a finished product that is one solid and continuous unit.

A side area has a single post mounted handrail using the same techniques.

The wall areas have a single post mounted handrail that not only follows the steps down flight by flight but also follows the corner of the wall. Again, this area was welded and polished back on site to provide a single and continuous run with no visible or mechanical interfaces.

- PROJECT:

- ASF Bespoke Stainless Steel Railings, Bradford Town Hall

- CLIENT:

- Bradford Metropolitan Council

- INFO:

-

As part of Bradford's city centre regeneration, ASF have for many years supplied a whole range of products ranging from Bollards and Litterbins to tree protection and post and rail / perimeters.

ASF were approached with drawings from Bradford Council detailing highly decorative art deco railings for the area around Bradford Town Hall

- PRODUCTS

& SOLUTIONS: -

ASF worked to these drawings to produce a very heavy duty, but visually striking railing that bordered garden areas, walkways and in areas ran along parapet walls.

Each railing was manufactured individually on hand made jigs, from marine grade 316 stainless steel.

The complicated nature of the railings meant they had to be painstakingly hand polished to achieve a long lasting satin shine.

- PROJECT:

- Leeds Brewery Wharf, ASF Sandringham 2 Rail Post and Rail

- CLIENT:

- Leeds City Council

- INFO:

-

Leeds Brewery Wharf is a vibrant City Centre Development on the Leeds waterfront, offering retail, dining, accommodation and leisure facilities. ASF were approached to supply the 2-rail version of the ASF Sandringham Post to run beside the footpaths along the city banks of the River Aire.

- PRODUCTS

& SOLUTIONS: -

The ASF Sandringham Post is a traditional style cast iron post available in a number of post and rail / post and panel formats. The 2 Rail version was chosen as it is a decorative post that forms a clear barrier without imposing too much on the riverside views, cityscapes and landscapes. The traditional post design also compliments the impressive arch of the Cast Iron Parapets of Leeds Bridge.

Manufactured in engineering grade 250 cast iron from 100% recycled sources, the posts offer a strong and incredibly long-lasting post and rail system - the posts are expected to last way in excess of 100 years in normal use and with minimum maintenance

Curves, gradients and corners were easily accommodated either by simple adaptions to the posts or by tube manipulation of the rails.

- PROJECT:

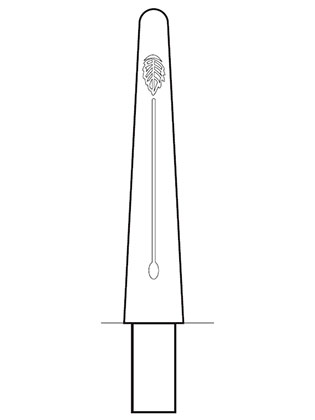

- Leaf Motif: Bespoke Recycled Cast Iron Bollards, Whitwood.

- CLIENT:

- Groundwork Wakefield

- INFO:

-

The urban design department of Groundwork Wakefield approached ASF with a design for a new cast iron bollard. They put forward a clean and tapered bollard style offering a modern look, that was to be embellished with a leaf motif and stylised elongated teardrop beneath.

- PRODUCTS

& SOLUTIONS: -

ASF took this design idea, and our pattern makers hand carved the pattern to turn the concept of the bollard into a mould for the finished product. Pattern makers are not just replicating a design, but also producing a pattern that will mould - taking into consideration metal contraction as it cools, where the mould will be split (it needs to be moulded in 2 halves that then cast as a single piece), and working out how the moulds need to taper to allow the molten metal to run freely into all parts of the desired design.

Once the pattern work was completed a sample was produced for approval. This was well received by the client.

Bollards were then put into manufacture. As with all ASF cast iron products the bollards were manufactured in 100% recycled, engineering grade 250 cast iron - the vast majority of our castings are made up of recycled car brake discs and in house returns, offering a much higher quality of iron than is necessarily needed, whilst still being completely recycled.

The outcome is a bespoke and stylish recycled bollard that will last for decades with zero to minimum maintenance and centuries beyond that with conservative levels of care.

- PROJECT:

- ASF 129 Recycled Cast Iron Bollards - Silsden

- CLIENT:

- Eric Wright Construction

- INFO:

-

ASF 129 Spherical Bollards were specified to run along the footpath edge of the road bridge crossing the River Aire on the western approach to the rural Yorkshire village of Silsden.

- PRODUCTS

& SOLUTIONS: -

The ASF 129 spherical bollards are a strong and physically imposing bollard with a spherical profile that remains subtle enough to sit unobtrusively in the picturesque Yorkshire countryside

ASF 129 spherical bollards are manufactured in 100% recycled cast iron, in our own on site foundry in Brighouse, West Yorkshire

The bridge has a gentle arch, and the spherical bollards follow this perfectly, complementing the pleasing nature of the rise and fall.

LE TOUR!

When the Tour de France Grand Depart came to Yorkshire the ASF 129 bollards joined in the party, with locals painting the bollards in Le Tour's lead rider colours:

King Of The Mountains - white with red spots

The Lead Sprinter - green

And of course the famed yellow jersey of the Overall (General Classification) Leader!

- PROJECT:

- Morrisons Supermarkets - Street Furniture

- CLIENT:

- Wm Morrisons PLC. Various Contractors

- INFO:

-

ASF worked alongside store development teams to specify and supply street furniture elements to store front, petrol filling stations and car park areas of superstores across the UK and beyond

- PRODUCTS

& SOLUTIONS: -

ASF have been supplying specified products to Morrisons Supermarkets for over 2 decades, originally (and still for the heritage stores) the ASF 101 M Logo Cast Iron Bollard, then over time ASF supplied the ASF 6003 Seat, the ASF 5002 Bollard, the ASF 8000 Cycle Stand and the ASF 7004 Litterbin to countless stores on the UK mainland and beyond.

The flagship product of this specification is the ASF 6003 Seat.

Profiled seat pan with fabricated arms. The seats are finished with satin brushed seating pans and bight polished arm and leg sections.

Fully welded, robust and stylish these seats have stood the test of time and are present at countless stores.

Manufactured in grade 316 stainless steel from recycled sources.

- PROJECT:

- ASF Bronze Street Furniture, Crowle Market Square, Lincolnshire

- CLIENT:

- Crowle Market Place Delivery Group

- INFO:

-

ASF were approached with an 'open book' brief to assist in the development and the production of a range of street furniture for the Crowle Market Square refurbishment.

The brief asked for products to be finished with a whole material look - meaning they are unfinished beyond minimal aesthetic cleaning / polishing to ensure a consistent and even appearance. At the early stages no actual material was specified.

The project required a feature paving strip, step units, sign posts, cycle stands and edgings for tree surrounds.

- PRODUCTS

& SOLUTIONS: -

ASF conducted meetings and foundry tours at our office / foundry site in Brighouse as a process of research and indeed inspiration, looking at finished cast products and samples in a range of materials and grades of materials. The client left with several ideas, but bronze (grade TBC) was the favourite material choice from that point.

ASF looked into various bronze grades for the applications required and settled on a gunmetal - LG2 bronze. An alloy of copper and zinc originally used in gun making, also popularly used in pressure valves and real ale hand pull pumps. Machinable and versatile, and available as ingots to cast as well as pre cast bar, this grade offered all the flexibility needed to meet the needs of the project.

ASF produced new patterns for the feature paving strip and the edging sections and bought in concast bronze bar to machine into cycle stands, sign posts and step units.

The feature strips were cast in sand moulds using traditional methods and supplied in metre lengths. They were fully unfinished and supplied as a sand casting to patina and polish over time with the passage of foot traffic. The edging strips were manufactured along the same lines, but the top edge lightly polished to give them a more uniform finish and also add a little 'pop' as the installed visible edge would only be very narrow - they will also patina and polish with time, but the polishing gave them a head start.

The remainder of the products were manufactured using pre cast bar that is supplied ready with a brush polished finish. Bar elements were machined to interconnect perfectly with one another and mechanically fixed with bright stainless steel coach bolts - the decision being to celebrate the precision engineered interfaces rather than try to hide them.

Products were supplied and installed into the refurbished market square on time and on budget, where, as alloys, they will last indefinitely and continue to patina, their look evolving over time.

- PROJECT:

- NOMA Project, Manchester

- CLIENT:

- Planit Design / The Casey Group

- INFO:

-

The NOMA project is a 20-acre mixed-use redevelopment scheme in the centre of Manchester - one of Britain's busiest and most vibrant urban environments. It incorporates innovative urban design, structures and spaces, and is designed as a location to live in and to be creative, as well as a destination to visit for shopping, eating and entertainment.

ASF had already manufactured stainless steel tree grilles for NOMA, and as such were approached by Planit Design and The Casey Group to develop and manufacture bespoke and highly decorative bronze tree grilles.

Based on drawings supplied by Planit Design, ASF were tasked with specifying the manufacturing process for the grilles and the grade of bronze that would be most suited for the project.

- PRODUCTS

& SOLUTIONS: -

ASF have been manufacturing tree grilles for decades, and used this experience to solve the practical issues presented by bronze - a material that doesn't readily lend itself to use in a tree grille application.

Bronze is a relatively 'soft' alloy that has a high resistance to corrosion but will also continually patina and change in physical appearance - starting out as a medium bright metal of red / pink colour in its raw state, the surface will oxidise over time creating weathered colours that range from lime green to deep dark browns.

The rate and colour variant of this oxidisation depends on a number of factors, partly the composition and grade of the bronze, but largely as a response to local climatic, geographical and environmental conditions.

After some consideration, ASF eventually proposed PB102/EW541K, a grade of bronze known for high fatigue strength and ductility.

Whilst the ductility makes the bronze very durable, it also means it can bend out of shape relatively easily so the next challenge was to design a sub-frame that would offer the necessary support. It was decided that a simple ladder frame be manufactured - consisting of heavy duty box section supports seated in an angle outer support frame.

Additional support was needed for the delicate areas of the design, so the bronze was mounted on a sheet of black coated steel that was then laser profiled to match the intricate design of the visible bronze tree grille.

To fix the whole structure together, ASF had security fixings bespoke manufactured in the same grade of bronze as the grille tops, meaning that the fixings themselves would oxidise at the same rate and in the same colour pattern as the grilles.

ASF supplied three bronze tree grilles on time and on budget to grace one of the most exciting urban developments in Britain. Due to the nature of the material the grilles will evolve, oxidise and patina as the development matures, and indeed as the trees they protect also grow, flourish and change.

- PROJECT:

- Next Wave Scheme: Adonised Aluminium Post and Rail, Bexhill on Sea

- CLIENT:

- Rother District Council / HTA Architects

- INFO:

-

HTA Architects designed the Next Wave scheme to renovate the seafront and public realm surrounding the Grade 1 listed modernist De La Warr pavilion. The CABE Seachange Funded project which aims to make the area a more attractive place for residents and visitors to Bexhill, and a catalyst for economic regeneration of this seaside resort.

When Bexhill on Sea needed a new barrier for the seafront promenade, Architectural Street Furnishings (ASF) were contacted to look at the project.

For harsh coastal environments, ASF would typically advise the use of cast iron products, however the client brief requested the barrier was constructed from aluminium, in a design that was sympathetic to the architecture of the De La Warr pavilion.

- PRODUCTS

& SOLUTIONS: -

Aluminium is not renowned for being particularly durable in coastal environments. To ensure the barrier would withstand the environmental conditions over time, ASF had the aluminium hard anodised.

The anodising process involved the immersion of aluminium in a bath of sulphuric acid (an electrolyte) and running a low voltage electrical current through the bath. Normal anodising results in a thin coating of aluminium oxide (rust) on the surface of the material, hard anodising is achieved by cooling the solution to freezing temperature and increasing the amount of electric current that is passed through the bath.

Hard anodising produces a much thicker coating of aluminium oxide, rendering the finished material only a few hardness points below diamond and protecting it against harsh environments such as the salt at the coast.

The client agreed the simple clean lines of the design and a machined aluminium cap was added to finish off the modern and stylish barrier.

The finished result is a low maintenance, minimalist seafront barrier that will not pitt or corrode over time.

The use of anodised aluminium enabled the client's brief to be matched without the need for compromise.

- PROJECT:

- Elk Mill Retail Park, Oldham - Bespoke Stainless Steel Sheep Cycle Stands

- CLIENT:

- Lindum Construction / Vector Design

- INFO:

-

In the second half of the 19th Century Oldham became the world's most productive textile producing centre, and by 1911 the town hosted an incredible 16.4 million spindles housed in over 360 mills. Elk Mill was the largest of these mills.

Elk Mill has recently been converted into a modern retail park offering big brand shops and a selection of dining options, but its glorious past is not forgotten with various tributes that point to the regions impressive textile history. ASF were approached by Vector Design to manufacture a modern cycle stand to help in doing just that.

- PRODUCTS

& SOLUTIONS: -

The silhouette of a sheep was chosen to be manufactured in stainless steel; the sheep, standing large and proud, looks backwards over its own shoulder - a nod to the heritage of this historically significant site.

Specifier, Vector Design had struggled to find a manufacturer who could take on this project and contacted ASF to see if it was feasible. At this stage the method of manufacture was still up in the air and a number of options were investigated. Most methods were either massively expensive or limited in some other way - timescale being a key issue. ASF had to find a solution that was both within budget and time restrictions yet still produced a great looking product that was robust enough to endure the rigors of a busy retail park.

It was decided that a single skin, heavy duty one piece unit was the best option.

The sheep shaped cycle stands are manufactured in 20mm thick, grade 316 stainless steel. They are produced by plasma profiling 20mm thick stainless steel sheet, using computer numerically controlled machinery, and are finished hand polished. A process that itself blends the modernity of the project and material with the hands on skills of past industrial times.

Designed to be cast directly into the ground, grouting voids were profiled into the base below ground level for added stability, as well as holes to site rebar anchors for even more security and stability.

Once manufactured the sheep silhouettes weigh in at a hefty 69kg each of solid stainless steel.

The finished articles have met the brief and offered an artistic installation that has a definite practical application, modern in appearance but clearly referencing the history of the site and the region as a whole.

The heavy duty, high grade stainless steel finished hand polished offers a low maintenance and extremely robust product expected to last for decades.

- PROJECT:

- Bespoke Cast Iron Ground Compass

- CLIENT:

- Leeds City Council

- INFO:

-

Leeds City Council were constructing a new 'South' entrance for Leeds Central Station and requested a bespoke cast iron ground compass as a centrepiece. The compass was to be embossed with selected international, national and local place names, cities and points of interest, as well as key historical facts.

The requirement was that the compass be supplied in SG (Ductile) Cast Iron and left in a bare metal state to patina and weather over time.

ASF were approached with drawings already completed, to interpret and turn into the finished product.

- PRODUCTS

& SOLUTIONS: -

As a bespoke product in cast iron, the first task was to produce a pattern.

The compass was planned in base sections - themselves totalling 17 parts, comprising a central rose pattern, 8 central surrounds, and 8 large outer spokes which housed the directional feature arms. In addition to this, a pattern for each directional arm had to be produced, which took the pattern sections to over 70 in all and included 1786 individual letters - all produced and mounted by hand by ASF's own in house pattern making specialists.

The manufacturing process then requires sand moulds to be taken from the patterns. For this to happen the pattern is mounted in a box which is then rammed with sand mixed with furane resin (a setting agent) - this leaves an inverted imprint of the pattern that is ready to take the molten iron.

Each of the 17 base patterns - mounted with the directional feature arms, were cast individually on a 'one casting a day' basis, quality checked and the next section boxed and set for moulding.

The castings are then shot blasted and dremelled by hand by the pattern makers to ensure they are exactly as per the original drawings supplied.

The ground compass is set into feature paving at the new south entrance of Leeds Station, where it expected to last many lifetimes.

- PROJECT:

- St Michaels Church Communal Area, Mytholmroyd

- CLIENT:

- Calderdale Council

- INFO:

-

Calderdale Council invited ASF to a planning meeting regarding the public area adjacent to St Michaels Church, Mytholmroyd.

An area was undergoing re-paving and renovation that would require a number of street furniture elements - the specification at this stage was pretty open with a general thought towards polished stainless steel combined with timber.

There was a need for seating, tree grilles, cycle stands, a step handrail unit and a length of quayside post and rail to core fix to a knee high retaining wall along the river bank

ASF was given a fixed fee and asked to offer some design solutions

- PRODUCTS:

-

Firstly, ASF produced a range of product drawings - some from standard range items and some completely bespoke. These were accepted in theory by the client. ASF conducted a number of site visits, some with and some without the client. Once the site was surveyed, measured and drawn a final specification was developed:

SEATING

The stylish ASF 6012 seat was used, 6 in total. Manufactured in grade 316 stainless steel from recycled sources with timbers in non tropical, non endangered hardwood.QUAYSIDE POST AND RAIL

This was designed as a modified ¾ height version of the usual ASF 211 quayside post. Manufactured in grade 316 stainless steel from recycled sources the design core fixes into the retaining wall and has a permanent cover plate to over the fixing area. The rail sections are a combination of stainless steel tubing and tension cables. Installation required a fair amount of onsite welding, so ASF brought in a mobile polishing company to finish the job to a high standard after installation.POST AND GLASS PANEL

Abutting to one end of the quayside post and rail is an area of cantilevered stone paving overlooking the river. ASF custom manufactured a section of stainless steel and glass feature post and panel to connect cleverly into the curved profile of the quayside post. Again, manufactured from grade 316 stainless steel from recycled sources.TREE GRILLES

There was simply not enough in the budget for stainless steel tree grilles, so ASF manufactured ASF 327 cast iron tree grilles in our own on site foundry. These are manufactured in 100% recycled cast iron and to follow the polished metal theme of the other products, were finished in a slow heated clear lacquer, preserving the gun metal effect of the newly poured cast iron.STEP UNIT

One end of the site has a set of steps to a footpath and bridge over the river. ASF produced a bespoke stainless steel handrail for this.CYCLE PARKING

The ASF 8000 stainless steel cycle stand was used to provide secure cycle parking on the site

- PROJECT:

- Ruthin Art Trail - Bespoke Laser Cut Tree Guards

- CLIENT:

- Lucy Strachan - Artist

Fred Baier - Artist

- INFO:

-

The Ruthin Art Trail is a partnership between Cadwyn Clwyd, Denbighshire County Council, Ruthin Town Council, with support from Bro Rhuthun Funded by Arts & Business Cymru, Arts Council of Wales Lottery and Cadwyn Clwyd

The Ruthin Art Trail was designed to encourage visitiors to the centre of Ruthin and develop community links with the craft centre.

Part of this programme was the restoration of an avenue of trees along Market Street.

Artists Lucy Strachan and Fred Baier approached ASF with conceptual drawings of bespoke tree guards for this part of the project, with a view to using them in conjunction with the ASF 303 tree grille - with a brief to not only produce the guard, but find a method to invisible fix the guards and grilles together.

- PRODUCTS:

-

The guards were manufactured in 275 carbon steel from recycled sources (a structural grade of steel). These were laser cut and rolled in two halves, to the correct diameter. The halves were then put together as bare metal and hand blended so that each section flowed perfectly, and the pattern was continuous through the full 360 degrees.

At the same point a bespoke frame was manufactured to house the ASF 303 tree grille and offer a shoe type guard fixing with all bolts hidden - so the attachment between grille and guard was not visible once the unit was installed.

The frames were finished galvanised and powder coated, and the grilles finished in metal primer and metal-shield top coat. The guards were hot dip galvanised, then acid etched and hand finished in a grey matt undercoat and pearlescent top coat as specified by artists Fred and Lucy.

ASF 5006 Steel bollards were manufactured form the same 275 carbon steel as the guards, and finished powder coated in a semi metallic grey.

- PROJECT:

- Widening, strengthening and refurbishment of Cleggford Bridge, Dewsbury - 2010

- CLIENT:

- CR Reynolds / Kirklees MBC

- INFO:

- The Grade II listed Cleggford Bridge is a 5 span arch bridge originally built in 1778 using stone masonry ashlar dressings. It was widened in 1889 at which point a cast iron parapet was fitted. ASF worked alongside CR Reynolds, the main contractor, Civil Engineers from Kirklees MBC and English Heritage in the renovation, refurbishment and re-strengthening of this cast iron parapet.

- PRODUCTS / SERVICES:

- Following extensive site surveys and test excavations the parapet needed to be delicately uplifted. This required the smelting out of Victorian leaded fixings and careful removal of hot rivets - a fixing method that was never meant to be removed! At this point careful attention was paid to numbering and ordering of bridge sections (over 100 in all, each one a different size, extending to over 200 metres in total length) to ensure they could be replaced in exactly the same order.

The whole bridge parapet was then brought to ASF's factory site in Brighouse for refurbishment. Firstly, a full metallurgists report was completed giving the chemical analysis of the Victorian iron, this meant that replacement parts could be manufactured to match as near as possible the original product.

The refurbishment began with shot blasting, by hand, the whole parapet followed by a survey of work to be done. The value of having our own skilled casting engineers, pattern makers and a metallurgist became invaluable as ASF managed to rescue 100% of the original panels. This was done by manufacturing individual cast iron sections and spindles to retro fit into the Victorian panels. A number of the older, weaker, and damaged spindles were also saved by the internal fixing of bright bar in a machined hole through the centre of the spindles. ASF saved around 50% of the posts using similar methods and employing a modular system for post sections, so that only those parts of the bridge parapet that were absolutely beyond rescue needed to be fully replaced.

The parapet was then re-fitted and returned to its former glory on the newly widened and strengthened Cleggford Bridge.

- PROJECT:

- Blackburn Town Hall, Blackburn

- CLIENT:

- Capita Symonds, Blackburn

- INFO:

- ASF worked closely with the client to develop a bench and seat which would be capable of withstanding the rigours of a busy city centre square. By using three different materials and their contrasting properties, a co-ordinated bench and seat design was developed. A co-ordinating granite bollard was used from our Cubist range which complimented the bespoke bench and seat designs.

- PRODUCTS:

- The Bespoke Seat and Bench were manufactured using flame finished Silver Grey Granite Pedestals, Iroko Hardwood Timber Slats and Steel Brackets. All fixings were made to be either invisible or anti tamper. The bollards used were our Cubist 150 in Silver Grey Granite, Flamed Finish

- PROJECT:

- Sale Town Hall, Sale

- CLIENT:

- HLM Design, Sheffield

- INFO:

- In order to modernise Sale Town Hall frontage and surrounding areas, ASF worked with the client to adapt established stainless steel range items to be used in a series of eye catching formats. Marine grade stainless steel was the chosen material as it is very low maintenance and offers the required contemporary look.

- PRODUCTS:

- Utilizing the ASF 5008/114 stainless steel bollard with satin brushed bases and highly polished machined tops, combined with the ASF 5050 stainless steel telescopic bollard to allow vehicular access, a coordinated scheme was developed. Chain barrier systems were also used to cordon off certain areas.

For permanent barrier areas, the ASF 5006 stainless steel bollard was chosen with 50mm diameter stainless steel rails as a complimentary scheme. At the front of the Town Hall perforated stainless steel panels were added to create an architecturally pleasing barrier. ASF 5006 step units were also used at the front of the building.

- PROJECT:

- Llanelli Seafront

- CLIENT:

- MacGregor Smith

- INFO:

- The ASF team was commissioned to help in the design of a range of modern cast iron posts for use both along the seafront and on top of a series of visually stunning look out towers. Three different but coordinated post styles were designed. In this extremely harsh environment a robust and high quality finish on the posts and rails was imperative.

ASF investigated the possibility of centrifugally galvanising the posts. Together with the use of marine grade stainless steel rails, separated from the cast iron posts via integral nylon sleeves in order to avoid any inter-metallic reaction, this proved extremely successful.

- PRODUCTS:

- The posts used were hybrids of our popular ASF211 post incorporating marine grade stainless steel rails. The cast iron was centrifugally galvanised to protect against both rusting and deterioration caused by the marine environment. The stainless steel rails were satin brush polished to a maximum RA value of 0.5 to reduce the risk of contamination.

This project was installed 8 years ago and is monitored regularly. The posts show absolutely no signs of deterioration and have dulled to a rich cast iron patina which together with the stainless steel looks superb. The system has required no maintenance during its eight years in this harsh salt water location.

- PROJECT:

- Llanelli Seafront - 14 years on

- INFO:

-

ASF's sub-contract spin galvanising company (BE Wedge) revisited the Llanelli Millennium Park site after 14 years to take measurements on how the spin galvanising of cast iron posts had stood up to the harsh marine environment.

The Llanelli seafront site was visited on Friday 31st October 2014 for a full inspection.

The general appearance is remarkably good with absolutely no signs of distress from the galvanised coating on any of the posts. The surface colour remains a rich dulled grey patina. This is even more impressive when considering the position of some of the lower posts at the step access to the beach and their proximity to the continual sand and salt water spray.

Random coating readings were taken on the posts positioned on the towers, and on the posts backing on to the beach. The average thickness reading for the tower posts was 223 microns (with the lowest reading being 193 microns), the average for the beach posts was 208 microns (with the lowest being 183 microns).

These readings remain well above today's required standard and, based on their corrosion rate, should give a further 40 years of service before any maintenance is required. This is doubly impressive considering that even when the galvanised coating does begin to deteriorate, it will leave a cast iron post, a material that can be expected to last 100 years in normal use, with minimum maintenance.

These posts are also 100% recycled and 100% recyclable. Cast iron, although one of the oldest of engineering and architectural materials, remains one of the most practical, environmentally sound and in many ways modern materials there is.

ASF manufactures its castings in the UK and the products have only delivery miles on their carbon footprint. In ASF's Brighouse foundry the raw material travels 20 metres across the factory floor to be turned into finished product.